APEX Turbine is the Official Dynamic Data Acquisition Supplier for The University of Notre Dame Turbomachinery Laboratory. The installed APEX solutions, designed for turbomachinery testing and research, include 544 channels across eight systems. Historically, turn-key systems have been delivered using a combination of General Standards digitizers and PFI signal conditioning with Datatel Telemetry, operated by APEX DS and DR software.

With a focus on future upgrades and expansion, UNDTL has selected a more modern APEX solution for an upcoming hypersonic test. Due to the multi-functional capabilities and ease of expansion, UNDTL chose Mecalc hardware powered by the new APEX DX+ software. This choice ensures compatibility with their existing APEX systems while establishing a foundation for future growth, utilizing the most advanced complete solutions available. Additionally, UNDTL made a significant investment in APEX analysis tokens, granting access to the full suite of APEX analysis products such as Gagemap, DX+, DX, and BT.

The University of Notre Dame Turbomachinery Laboratory (UNDTL) is a premier research and development facility dedicated to advancing the field of turbomachinery. Located in South Bend, Indiana, UNDTL is renowned for its cutting-edge research and state-of-the-art testing capabilities. The laboratory focuses on the development and testing of propulsion systems, energy generation, advanced thermal management, and energy storage solutions. With a strong emphasis on collaboration, UNDTL partners with industry leaders and government agencies to drive innovation and address the complex challenges of modern turbomachinery.

In recent years, UNDTL has made significant strides in expanding its research capabilities into the realm of hypersonic testing. The laboratory has constructed two new test cells specifically designed for the research, development, and testing of hypersonic propulsion systems. These facilities are equipped to handle high-Mach air-breathing propulsion systems, including ramjet and scramjet combustion systems. This expansion into hypersonic testing positions UNDTL as a critical resource for the development of high-speed flight engines and hypersonic aviation.

UNDTL’s hypersonic testing facilities are part of a broader initiative known as the Hypersonic Systems Initiative. This initiative encompasses research related to all aspects of hypersonic flight, from structures and materials to thermal protection, energy storage, aerodynamics, signatures, and long-range diagnostics. By leveraging its expertise and advanced infrastructure, UNDTL aims to contribute to the development of reusable hypersonic vehicles and enhance the nation’s strategic defense capabilities.

The 16-channel Mecalc hardware system delivered is designed to provide high-performance data acquisition and signal conditioning for a variety of testing applications. This system includes the following components:

DecaQ-04 Mainframe

The DecaQ-04 is a 4-slot chassis and controller that supports up to twelve QuantusSeries I/O modules. It features a rugged machined aluminum chassis for field use, conduction/convection cooling with external fans, and no internal airflow. The mainframe includes a PQ Chassis Controller/Power System, Ethernet 1000BASE-T, and is PTP IEEE 1588-2008 (Precision Time Protocol) capable.

DQ-BAT52

The DQ-BAT52 is a battery pack designed for the independent DecaQ mainframe. It is user-removable and swappable, providing uninterrupted power supply (UPS) to continue operation during power fluctuations. The DecaQ-04 supports one to two DQ-BAT52 batteries.

SC42S G2

The SC42S G2 is an advanced signal conditioning interface that supports up to four I/O modules with a throughput of 10MB/s. It includes data management, re-sampling, synchronization, linearization, and precision power sources.

WSB42X G2 (x 4 cards)

The WSB42X G2 is an advanced bridge/ICP®/voltage input module with four input channels. It offers 24-bit resolution, up to 204.8 kSa/s per channel, and 100 kHz bandwidth. The module supports various modes, including bridge excitation (full, half, and quarter), LVDT mode, ICP® mode with 4, 8, or 12 mA constant current at ±12 V excitation, and voltage mode with AC or DC coupling. The input ranges for all modes are ±(10 mV, 100 mV, 1 V, 10 V).

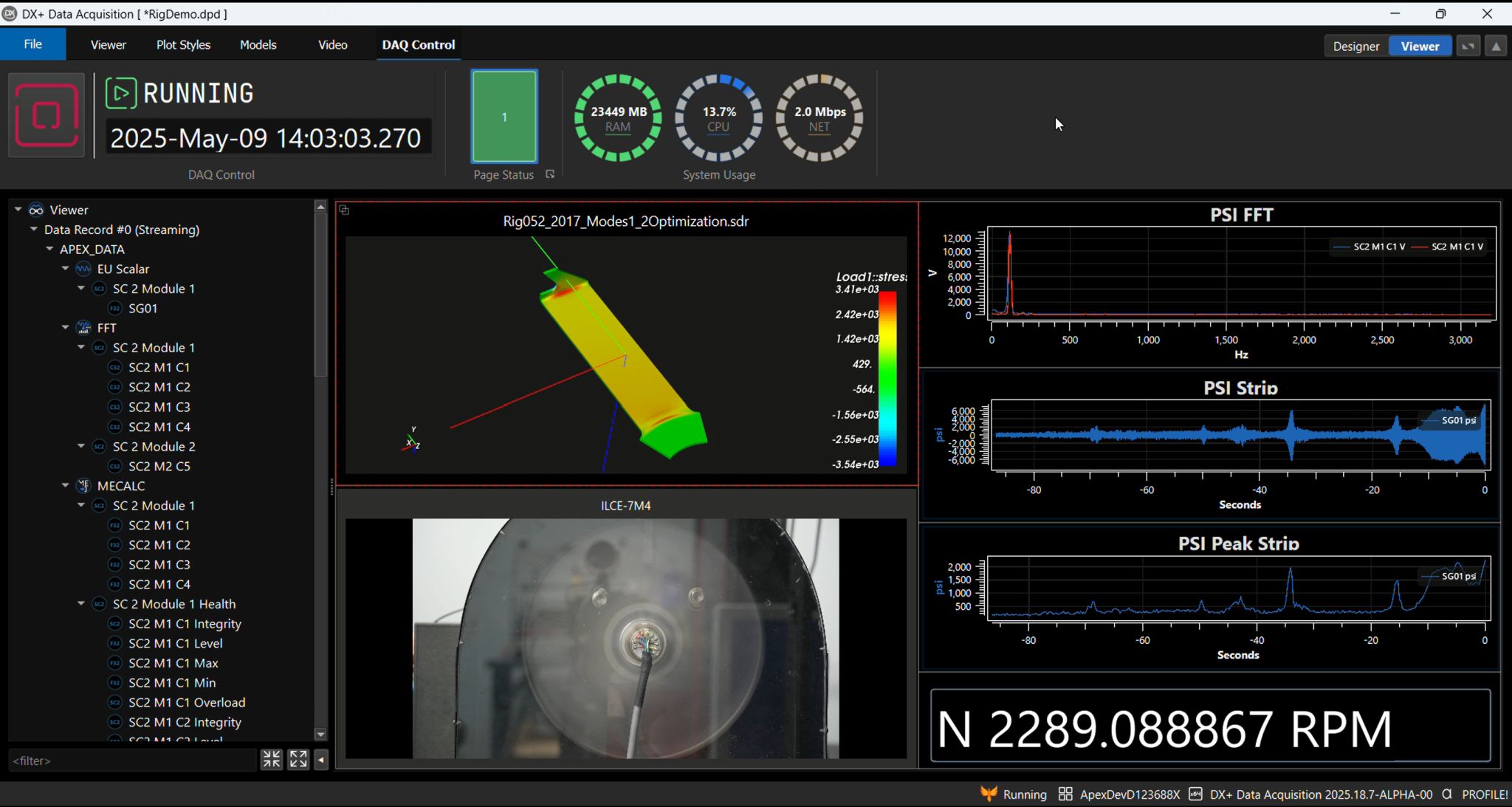

- Test, Measurement, Analysis, and Reporting: An all-in-one tool that integrates various measurements (temperatures, pressures, strain, valve positions, fuel flow, thrust) with video and 3D modeling to provide a comprehensive view of engine tests.

- Dynamic 3D Imaging: Computer modeling and CAD imaging for advanced data fusion.

- Color Mapping: Based on direct measurements or limits.

- Interactive Overlay and Model Elements: Toggle sensors on/off and select sensors or groups to see exact values on traditional plot types.

- Open Architecture: Data distributed using an open architecture and recorded directly to a database for flexibility, data analysis, and user control.

- CMMC-Ready: Provides a secure environment and information/data access control for in-house and third-party test analysis software applications.

- Customizable Real-Time Data Analysis: Allows discipline-specific engineers to monitor key success parameters continually and adapt to new discoveries.

- Integrated Modeling & Simulation: Provides vehicle-centric visualization of important metrics with easy access to underlying measurements.

- Advanced Data Analysis Capability: Turns test data into usable knowledge leveraging AI/ML and software-embedded subject-matter-expert knowledge.

- Video and Modeling Overlay: For advanced data fusion.

- Color Mapping: Based on direct measurements or limits.

- Advanced Data Analysis Capability: Seamlessly turns test data into usable knowledge. Analysis tools leverage AI/ML and software-embedded subject-matter-expert knowledge.

- Modular, Open, Distributed Network Architecture: With open interfaces and database specifically designed to be deployed within edgenet applications.

- CMMC-Ready Digital Backbone: For aerospace systems testing provides a secure environment and information/data access control for in-house and third-party test analysis software applications.

- MeCalc Integration via Direct Connect Driver enables integration and communication between the APEX software and MeCalc devices, ensuring efficiency and reliability without compromising performance or data productivity, which is often a challenge when integrating high volumes of dynamic data through open protocols.

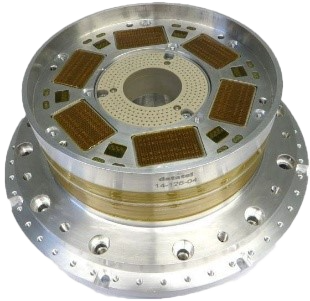

APEX has delivered several telemetry solutions designed, built, and assembled by Datatel for the University of Notre Dame:

Datatel Inline Telemetry Solution

- Max. 14,000 rpm @ 65°C

- 30ch. Kulite pressure transducer, 50ch. dynamic strain gages, 50ch. thermocouple, 5ch. RTD for cold junction compensation (CJC)

- Digital output of test data via Ethernet

Highspeed Shaft-End Telemetry Solution

- Max. 30,000 rpm @ 125°C

- 30ch. dynamic strain gages, 30ch. thermocouple, 3ch. RTD for cold joint compensation (CJC)

- Installation at the end of the shaft with a Superbolt in the center

Shaft-End Telemetry Solution

- Max. 17,000 rpm @ 125°C

- 50ch. Kulite pressure transducer, 10ch. dynamic strain gages, 10ch. thermocouple, 1ch. RTD for cold joint compensation (CJC)

- Intermediate splicing pad for Kulite’s temperature compensation modules

APEX has been a supplier to the UNDTL for over 13 years, providing more than 500 channels of data acquisition using the following components:

General Standards 32-Channel Sigma Delta PCI Analyzer Cards

- 32-channel PCI-24DSI32 analog input board

- 24-bit analog input resources

- Sample rate up to 200 KSPS per channel

- 32 differential analog input channels with delta-sigma converters

- Linear phase digital antialias filtering

- Synchronous operation with all channels clocked simultaneously

- Internal sample rate generator

- Software-selectable input ranges of ±2.5V, ±5V, and ±10V

- 256 K-sample FIFO buffer

- Optimized for precision voltage measurements and complex audio signal analysis

Precision Filters 28000 Signal Conditioning Units

- Accurate signal processing and conditioning

- Designed for complex data acquisition tasks

- Robust and reliable performance across various testing scenarios

- Advanced filtering and amplification capabilities

APEX DS Software

- Seamless integration with hardware

- Comprehensive data management and analysis solutions

- Real-time data visualization

- Automated data processing

- Customizable reporting tools

- Met stringent requirements for accuracy, reliability, and scalability

APEX is proud to have the University of Notre Dame as a testing partner and customer continually advances the state of the art in turbomachinery testing.

To find out more about their lab, click here.

Contact APEX for a demo on how DX+ can